Build up workforce, grow slow in tough times

Amid lingering economic headwinds globally, enterprises should focus on restructuring and developing employee competence rather than expanding business, says CEO Nguyen Phuong Lam of construction and decoration firm Remak.

How were your company’s business activities in 2022, when the national economy started recovering from the pandemic but then confronted with global economic downturn?

It was a year with a series of unpredictable changes. Some thought the Vietnamese economy was like a spring compressed by the pandemic and that it would strongly bounce back post-pandemic. But the economy was moving in an unexpected way.

Strong global headwinds included political instability, high inflation, and China’s zero-Covid policy that has caused supply disruptions. In Vietnam, there was a credit crunch; the VND/USD exchange rate increased; fuel prices, shipping costs, and raw material prices increased dramatically. Orders from overseas markets declined.

However, from my point of view, after these unforeseen difficulties and uncertainties would probably come a time of opportunity. Therefore, it is important to be able to catch them in time. In addition, tough times helped the market say goodbye to weak and poorly managed enterprises.

At our own company, we did not focus on investment to expand our markets last year to pursue sales growth. Instead, we invested in our personnel, improved our services, quality, and processes, conducted R&D into new competitive products, and invested in a production system with modern technology, a higher level of automation to boost labor productivity and cut production costs.

As a result, we obtained growth of 150% in revenue and 120% in profit compared to 2021. In particular, our products introduced in 2022 gained wide acceptance from markets with lots of positive feedback. This boosts our hopes for a successful new year.

Why did you focus on sound-absorption and soundproofing? Does this remain an underdeveloped sector in Vietnam?

Starting operations in 2007, Remak was a micro business named Detech Company with just five people operating in consulting services, real estate brokerage, construction, and interior design.

After three years of inefficient operation, I saw that the real estate market was not really stable. There was a lack of creativity in products and services for construction and interior design. However, I realized that producing sound and heat insulation materials was a big opportunity because large amounts were imports. Import prices were high while it took time for the materials to become available on the market. I also found that they could be made in Vietnam at a cost equal to one-fifth of imports.

Consequently, Remak was established in 2012, aiming at providing materials with similar quality to imports but with prices equal to only 20%. We started Remak with a rented factory of only 500 square meters. Two years later, in 2014, we built a factory covering nearly 7,000 square meters in Hanoi’s Quoc Oai district.

In 2018, we built a new plant, with our new office, on a site of nearly 8,000 square meters in Lai Yen Industrial Park in Hoai Duc district, Hanoi. To date, we’ve become a leading maker, supplier, and installer of sound-absorption and soundproofing materials; we are also in the top-10 group in heat insulation in Vietnam. In the field, just a few Vietnamese enterprises are professional players with factories, machinery, technology, and a well-organized and professional workforce.

We built a new 1.6-hectare factory in Mong Hoa Industrial Park in Hoa Binh province in 2022, and plan to inaugurate it in early this year. It is expected that our work on the second plant in the IP would begin next year on a 3.5-hectare site so that we could expand production and our product line-up.

In addition, we operate warehouses in My Dinh area of Hanoi and in Hoc Mon district of Ho Chi Minh City.

What has helped you leave a footprint on the domestic market? And what makes your products any different from established imports?

Our products offer three features. Firstly, they are friendly to the environment and people. This factor helps the public know that we are responsible to the community and society, enhancing our position and prestige.

The second is innovation and creativity. If we don’t have this, we can only compete on price. But price competition will not provide companies with sustainable profits. Therefore, we have invested a lot in research and development to find new solutions, and develop innovative quality products with new functions at lower costs.

The third is to provide real customer value. This means you make contributions to the whole community and society, not just for your own business.

Together with the Institute of Development and Application for Sound Materials, we’ve been able to supply products to structures like terminal T2 at Noi Bai International Airport in Hanoi, Formosa thermal power plant, An Khe power plant, Samsung Thai Nguyen factory, Lam Giang yarn factory, Quang Chau Industrial Park, Honda Vinh Phuc factory, National Cinema Center, National Geriatric Hospital, and hall of the Air Defense Command.

We have given special priority to green materials and solutions. My company currently manufactures and supplies all kinds of environmentally friendly and recyclable materials like mineral wool, glass wool, XPS foam, wooden wool for goods packing, and sound-absorbing and soundproof wooden wool panels.

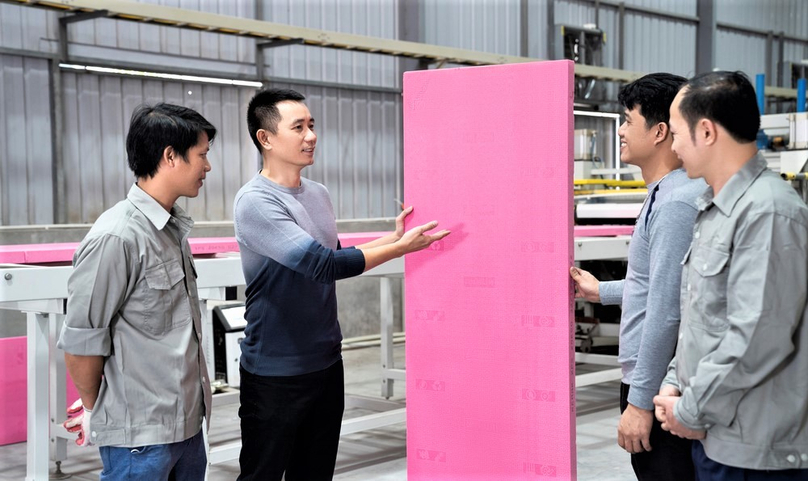

Remak’s XPS foam panels at its foam factory. Photo courtesy of the company.

XPS foam is our most outstanding product as it is used for soundproof, heatproof, and fireproof purposes. In 2017 or so, we decided to make XPS foam ourselves. But due to several reasons, including social distancing and supply disruption caused by the pandemic, we could not finish our XPS foam plant until October 2022 as one of the four factories producing this material in Vietnam.

Test results at the Ministry of Construction's Institute of Building Materials in November 2022 showed that our XPS foam has the highest capability among domestically made products in heat insulation, water resistance, compression, and bending resistance.

It is estimated that each year, each square meter of our XPS foam in use can reduce an electricity bill by around VND1 million ($43) in air conditioning costs.

We are also developing heat insulation and fireproofing materials. We will launch this year new soundproof and fireproof products that can be easily installed.