Beverage giant Tan Hiep Phat's 3Rs model for circular economy development

Tan Hiep Phat Beverage Group (THP) has implemented the 3Rs model of reducing waste, reusing, and recycling resources and products, as part of its sustainability strategy. The application of the 3Rs model in manufacturing andbusiness has been highly effective in resource saving, process innovation, creative development, direct business benefits and competitive advantage, wrote David Riddle, former acting CEO of Tan Hiep Phat Beverage Group (THP).

THP has been a pioneer in the development of the circular economy and has invested in the most advanced technology in the world with the highest automation capabilities to achieve its circular economy objectives, including economic efficiency and maximum circularity.

Known as aseptic cold-filled beverage production line technology, THP has, over several years, invested in GEA Procomac machines from Germany. Aseptic technology enables the highest product quality and nutritional benefits while maintaining stringent sterile requirements.

It has also enabled THP to minimize, as far as possible, the plastic used inproduction, by reducing the weight of plastic bottles. Another step that the group has taken, is investing in Washing -Extruder - Injection Moulding technology to recycle polyethylene (PE) and polypropylene (PP) plastic for pallet and garbage bin production, while also deploying an automatic, digitalized management system.

Leveraging its strengths in research, manufacturing, and creativity, THP aims to give waste a new life by using it to create products that can be used by the company. Meeting this objective will be achallenge which will involve nearly every department at THP.

Circular economy initiatives in the manufacturing process

In 2013, THP launched its lightweight bottle project where each bottle’s weight was reduced from 27 g to 21.8 g through research, design, and innovation. The company used the most advanced European machinery to create overall efficiency in performance, lowering manufacturing process loss, electrical energy, and waterconsumption.

Five years later, in 2018, the bottle weight decreased again to either 15.6 g or 13.2 g, depending on the product. The environmental impact of this initiative was tremendous, despite only a few grams of plastic saved from each plastic bottle.

Between 2013 and 2018, Tan Hiep Phat was able to cut plastic waste by 34,000 tons, and for the four years between 2019 to 2023, the saving was 44,000 tons, so in total 78,000 tons was cut over that nine-year period.

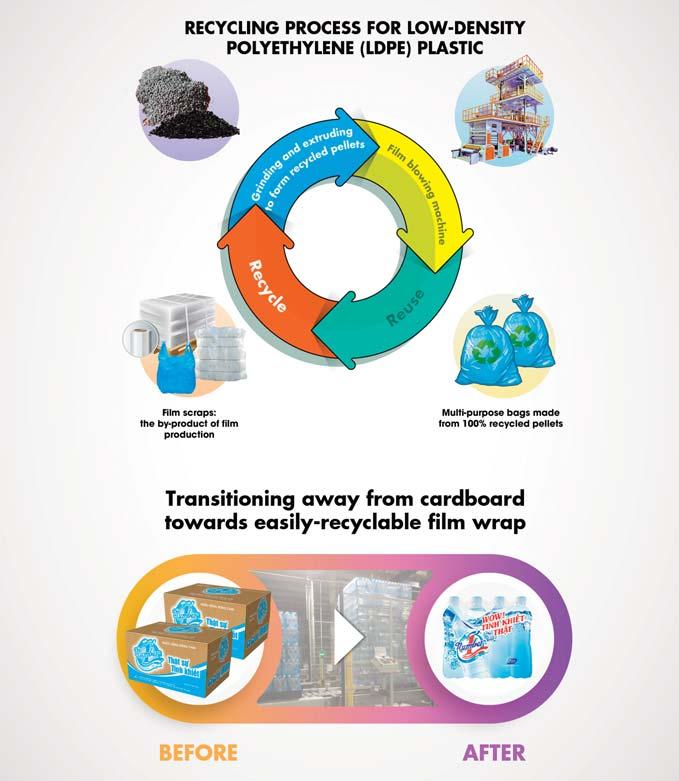

In parallel, shrink films and PE bags manufactured by the company are 100% recycled and reused for years as multi-purposebags for holding preforms, caps, and garbage bags. This has been the case since 2013. Shrink films, PE bags and by-products in the manufacturing processes are collected and through a grinding process are used to create recycled PE resins.

Through the process of blowing, welding, and cutting with modern blowing machinery, recycled resins become shrink wrap to pack bottles and multi-purpose bags used by the company’s seven factories.

In 2022, the company eliminated the use of carton boxes for Number 1 purified water and instead now uses only PE shrink wrap made from recycled plastic resins. In 2021 during the Covid-19 pandemic, the company started operating High-Density Polyethylene (HDPE), and PP recyclinglines.

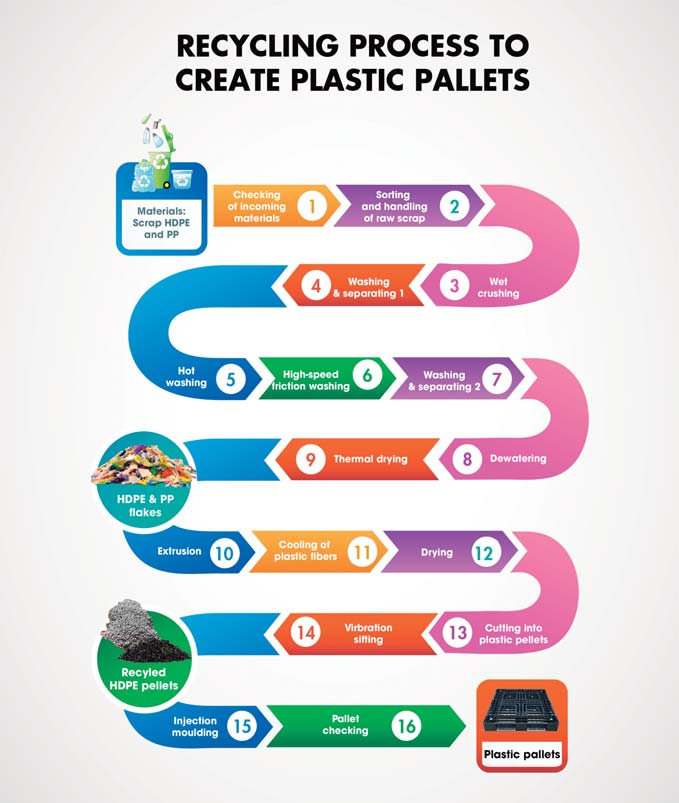

The current maximum recycling capacity stands at 300 tons of plastic per month. This production line is intended to produce plastic pallets from HDPE scraps. The production process consists of three main phases.

Phase 1: HDPE/PP/PET flake production

- Input materials used for HDPE/PP/PET (polyethyleneterephthalate) plastic scraps are supplied by a network of traditional scrap collectors and traders. The scraps then undergo a quality check to ensure they comply with the company’s material standards. In the first part of the process, the product is placed onto a sorting belt. It then passes through a metal segregator into a wet crusher, where scraps are mechanically crushed to meet the required size for the filter net below. Subsequently, the plastic pieces head to the firstfloating washing tank using a screw loader.

They then travel to the hot washing tank where the plastic scraps are washed with alkaline detergent solution to remove soluble dirt.

- Scraps then enter a high-speed friction washing machine where the pieces knock against each other at high speed to get rid of hard-to-remove contamination. Scraps are washed again in the second floating washing tank. The clean scraps then move into a horizontal dewatering machine which uses centrifugal force to spin water moisture off the plastic. This is followed by a thermal dryer at 110-130 degrees Celsius to achieve a humidity level lower than 1%. The last step before packaging is passing through two dust separators to eliminate fragments of labels, film, or fine dust so the resulting flakes are uniform.

Phase 2: Recycled HDPE Pellets production

- In the next stage of the process, flakes then enter the extruder, to be turned into plastic pellets. The extruder has a vacuum system to remove excess gas or vapour which may cause air bubbles in the resulting pellets.

The extruded plastics are cooled in the metal plate, and consequently pass through two drying fans before entering a pellet-cutting machine. Inside the cutting machine, lengths of plastic are cut into pellets smaller than 4 mm in size. The pellets pass through vibrating sifting machines to ensure the size of the pellets meets internal requirements and any other standards directed by potential customers.

- Recycled pellets are packaged and stored later to be used in the manufacturing of recycled products, commercialized or supplied to potential customers.

Phase 3: Recycled Plastic Pallets production

- A significant proportion of the pellets are then used to produce recycled pallets.

- Plastic pellets are fed into large extruder screw barrels specifically designed to create 100% recycled resin, to homogenize the plastic, before being injected into press moulds.

Molten plastic is used to fill the moulds using high injection pressure and a high clamping force of 30,000 KN (approximately 3,000 tons). The moulds are then cooled until the plastic becomes solid. They are then separated automatically by ejectors and robotically lifted out of the machine. The resulting plastic pallets are examined, stocked, and stored according to internal guidelines ready to be used within THP’s factories as needed by the logistic department’s stocking and transporting activities.

Environmental initiatives and achievements at THP

In summary, since 2013 THP has implemented several initiatives to recycle plastic, and at the same time to lower plastic use by innovating both a light bottle design and using thinner wrap in the manufacturing process. The overall aim is to reduce the amount of virgin plastic derived from petroleum such as PE and PET plastic in its production processes.

As mentioned before, during the first five years of implementing more sustainable practices, the company reduced its plastic use by more than 34,000 tons of plastic (2013-2018). In the subsequent four years, it reduced its plastic usage further, eliminating 44,000 tons (2019-2023).

The company has expanded its circular economy practices that help reduce environmental impact and reduce greenhouse gas through lowering single-use plastic usage and increasing the manufacture of recycled plastic products.

Recycled pallets and plasticresins are manufactured from more than 3,500 tons of PE and PP materials collected from the market in 2022. After 10 years of implementing the 3R model, from 2013-2022, THP has seen several significant benefits, both in achieving circular economy objectives and in concrete economic benefits. Our calculations suggest that the reduction we have achieved in the use of virgin plastic materials derived from petroleum is equivalent to an effective reduction of over 147,420 tons of greenhouse gases in the last nine years.

- The quality of the plastic we are creating in-house from our recycling processes now meets the standards we demand for internal use. We are also now in a position to commercialize some of our plastic products including plastic pallets and recycled resins. This gives us the opportunity to not only achieve a circular economy within THP, but also to support other companies in achieving their own circular economy goals.

Future circular economy goals and objectives at THP

THP has set an objective to reduce 112,000 tons of plastic before 2027 and will continue to expand its circular economy measures in conjunction with other plastic recyclers. Through its 3Rs model, THP is contributing to the development and integration of the circular economy following the “Circular economy development in Vietnam” Scheme issued by the Government on June 7, 2022.

At the same time, it is creating opportunities to collaborate with partners, including domestic and foreign manufacturing entities, to promote the expansion of the circular economy locally and overseas. The implementation of the 3Rs model helps to increase pride and ownership among THP’s employees, aligning with one of THP’s core values of social responsibility.

Future opportunities to increase circular economy implementation

While Vietnam is starting to see the benefits of the circular economy in helping to reduce waste and resource usage, there are still further policies and procedures that can be implemented to increase adoption. These fall into three broad categories:

Policies that compel businesses to implement the circular economy according to a specified roadmap

- Developing a policy framework to aid circular economy adoption. This could include rules on corporate responsibilities in collection, resource restoration from used products, economic tools, and policies such as resource taxes, and environmental protection fees.

- Completing legal provisions for the development of the circular economy. Suggestions include amending the Environmental Protection Law; defining the specific responsibilities of manufacturers and distributorsin retrieval, sorting, and recycling or paying waste management costs for discarded products based on the number of products sold on the market; managing projects based on their lifecycle; and establishing roadmaps for the development and application of environmental standards equivalent to those of developed nations in the region.

- Adding policies to control the price increase of inputs and outputs of recycled products, to avoid fierce competition among recycling companies who can produce official invoices, versus recycling facilities which have established a network.

- Controlling and monitoring the market. To encourage healthy competition and protect consumer rights, government agencies need to increase control and monitoring. This can help prevent non-compliance, create favourable conditions for corporations to engage in sustainable activities and increase consumer trust toward products and services.

- To expand the circular economy, manufacturers need to clearly determine what corporations’ top priorities are. The focus should be on durable and sustainable manufacturing processes, instead of manufacturing as quickly and cheaply as possible.

Product design should be convenient for recycling to avoid materials ending up in landfill. Policies that encourage enterprises to implement the circular economy by creating attractive conditions

- Establishing policies to incentivize investment. This will promote new business opportunities and attract domestic and foreign investors. These policies can include exemption from import taxes, capital support for new corporations, creating favourable conditions for start-ups and international collaboration.

Another option is to offer capital supply and financial support by incentivizing policies and rewarding corporations who are engaging in sustainable activities and who are making positive contributions to the community and environment.

- Planning industrial parks around a recycling value chain serving a specific geographical region.

- Developing an in-depth economic growth model, utilizing resources effectively, applying scientific technology within industries, to turn waste into renewable energy. Defining a roadmap to replace fuels and products using hazardous materials, single-use products with eco-friendly fuels and materials, reusable products, and extending products’ useful life cycle.

- Adjusting energy planning, slowly reducing dependence on energy derived from fossil fuels and hydropower; attracting selected investment projects based on manufacturing scale, manufacturingtechnology, environmental engineering, and project locations. Developing a roadmap to transform technology based on saving criteria, energy efficiency, and waste reduction.

- Connecting the value chain of planning and technical capabilities to serve the recycling industry at a scale appropriate for collection mechanisms. This should be specific to the geographical and economic traits of each region to develop a circular economy consistently and effectively.

- Standardizing the transportation costs of plastic waste to improvere cycling effectiveness at each factory in each region. This will lead to increased network-wide collaboration across geographical locations and decreased price competition among cooperatives or private entities who have established their activity chain in trading recyclablewaste on the market.

- Creating official invoices at collection facilities to standardize raw material pricing for circular activities when recycling different types of plastic waste. Communicating about the circular economy so that state offices, businesses, and people are aware of the need for and the positive effects of the circular economy

- Increasing awareness about the circular economy and the necessary requirements to transition to this model. Education about the circular economy could be increased from design to implementation in all industries, which would be agreed upon and aligned with leadership and management in each organization.

- Growing capital and human resources to transition to a circular economy. To develop a circular economy requires a knowledgeable team of experts to problem-solve processes end to end. Growing these teams and increasing the resources available to them will help Vietnamese corporations, especially SMEs, understand and implement the technologies required to establish a circular economy.

- Increasing the adoption of eco-friendly habits and behaviors by consumers and manufacturers. Clean manufacturing, responsible manufacturing, clean consumption and sustainable consumption are concepts mentioned in policy direction and legal provisions, but which are not yet commonly applied in everyday activities.

- Developing a Communication Strategy on the circular economyto increase manufacturers’ and consumers’ awareness of their responsibilities toward each product’s entire lifecycle. Education will raise awareness among consumers on source segregation, facilitation of collection and transportation to make reusing and recycling easier and more convenient.

- The implementation of the circular economy should happen together with developments in technology, the digital economy and Industrial Revolution 4.0. New technology will help to develop the circular economy model effectively, reduce pollution, preserve nature and biodiversity, prevent overexploitation of resources, and create opportunities for new jobs to ensure the model’s objectives are met.

The circular economy is a new movement which meets critical requirements to preserve our planet and resources for future generations. It is imperative that companies act quickly and proactively to address issues and implement workable solutions to achieve our collective circular economy goals in Vietnam.

- Read More

Japan food major Acecook eyes new plant in southern Vietnam

Acecook, a leading instant noodle maker with 13 plants operating across Vietnam, is studying a new project in Tay Ninh province.

Industries - Wed, November 19, 2025 | 9:39 am GMT+7

Vietnam’s largest Aeon Mall to take shape in Dong Nai province

Authorities of Dong Nai province, a manufacturing hub in southern Vietnam, on Monday awarded an investment registration certificate to Japanese-invested Aeon Mall Vietnam Co., Ltd. for its Aeon Mall Bien Hoa project.

Industries - Tue, November 18, 2025 | 8:17 pm GMT+7

Police propose prosecuting Egroup CEO Nguyen Ngoc Thuy for fraud, bribery

Vietnam’s Ministry of Public Security has proposed prosecuting Nguyen Ngoc Thuy, chairman and CEO of Hanoi-based education group Egroup, along with 28 others, for fraud to appropriate property, giving bribes, and receiving bribes.

Society - Tue, November 18, 2025 | 4:01 pm GMT+7

Singapore-backed VSIP eyes large urban-industrial complex in southern Vietnam

A consortium involving VSIP, a joint venture between local developer Becamex IDC and Singapore’s Sembcorp, plans a large-scale urban-industrial development named the "Moc Bai Xuyen A complex along the Tay Ninh-Binh Duong economic corridor in southern Vietnam.

Industrial real estate - Tue, November 18, 2025 | 2:38 pm GMT+7

Aircraft maintenance giant Haeco to set up $360 mln complex in northern Vietnam

Hong Kong-based Haeco Group, Vietnam's Sun Group, and some other partners plan to invest $360 million in an aircraft maintenance, repair and overhaul (MRO) complex at Van Don International Airport in Quang Ninh province - home to UNESCO-recognized natural heritage site Ha Long Bay.

Industries - Tue, November 18, 2025 | 2:13 pm GMT+7

Thai firm opens 20,000-sqm shopping center in central Vietnam hub

MM Mega Market Vietnam (MMVN), a subsidiary of Thailand's TCC Group, on Monday opened its MM Supercenter Danang, a 20,000 sqm commercial complex with total investment capital of $20 million, in Danang city.

Real Estate - Tue, November 18, 2025 | 12:20 pm GMT+7

Vietnam PM asks Kuwait fund to expand investment in manufacturing, logistics, renewable energy

Prime Minister Pham Minh Chinh on Monday called on the Kuwait Fund for Arab Economic Development (KFAED) to strengthen cooperation with Vietnam, particularly in the areas of industrial production, logistics, renewable energy, green economy, and the Halal ecosystem.

Economy - Tue, November 18, 2025 | 11:53 am GMT+7

Thai dairy brand Betagen to build first plant in Vietnam

Betagen, a famous Thai dairy brand, plans to build its first manufacturing plant in Vietnam, located in the southern province of Dong Nai.

Industries - Tue, November 18, 2025 | 8:49 am GMT+7

Banks dominate Vietnam's Q3 earnings season, Novaland posts biggest loss

Banks accounted for more than half of the 20 most profitable listed companies in Vietnam’s Q3/2025 earnings season, while property developer Novaland recorded the largest loss.

Finance - Tue, November 18, 2025 | 8:24 am GMT+7

Highlands Coffee posts strongest quarterly earnings in 2 years on robust same-store sales

Highlands Coffee, Vietnam’s largest coffee chain, delivered its best quarterly performance in two years, with Q3 EBITDA exceeding PHP666 million ($11.27 million), parent company Jollibee Foods Corporation (JFC) said in its latest earnings report.

Companies - Mon, November 17, 2025 | 10:21 pm GMT+7

Hong Kong firm Dynamic Invest Group acquires 5% stake in Vingroup-backed VinEnergo

VinEnergo, an energy company backed by Vingroup chairman Pham Nhat Vuong, has added a new foreign shareholder after Hong Kong–based Dynamic Invest Group Ltd. acquired a 5% stake, according to a regulatory filing on Saturday.

Companies - Mon, November 17, 2025 | 9:52 pm GMT+7

Thai giant CP’s Q3 Vietnam revenue drops 20% as hog prices slump

Thailand’s Charoen Pokphand Foods PCL (CPF) reported a sharp downturn in its Vietnam business in Q3, making the country its only major market to contract.

Companies - Mon, November 17, 2025 | 4:16 pm GMT+7

Surging demand for gas turbines tightens supply chains, extends lead times: Siemens Energy

Demand for gas turbines is rising rapidly, especially in regions with a surge in data center development, tightening supply chains and extending lead times - factors that investors must closely track during project preparation, according to Siemens Energy.

Companies - Mon, November 17, 2025 | 1:34 pm GMT+7

Novaland completes first phase of restructuring, targets 'returning to growth' from 2027

Novaland, a leading real estate developer in Vietnam, said it has completed the first phase of its multi-year restructuring plan and aims to finish the entire program by end-2026, positioning the company to return to growth from 2027.

Companies - Mon, November 17, 2025 | 12:26 pm GMT+7

Vietnam's property developer Regal Group to list shares on HCMC bourse in Q4

Regal Group JSC, a property developer based in the central city of Danang, has applied to list its 200 million RGG shares on the Ho Chi Minh City Stock Exchange (HoSE) in Q4/2025.

Real Estate - Mon, November 17, 2025 | 10:52 am GMT+7

Vietnam's upstream oil & gas stocks surge on project momentum, regulatory easing

Stocks of Vietnam’s upstream oil and gas companies have surged in recent weeks, boosted by rising exploration activity and new rules that accelerate project approvals, while midstream and downstream players face pressure from falling crude prices.

Companies - Mon, November 17, 2025 | 8:57 am GMT+7